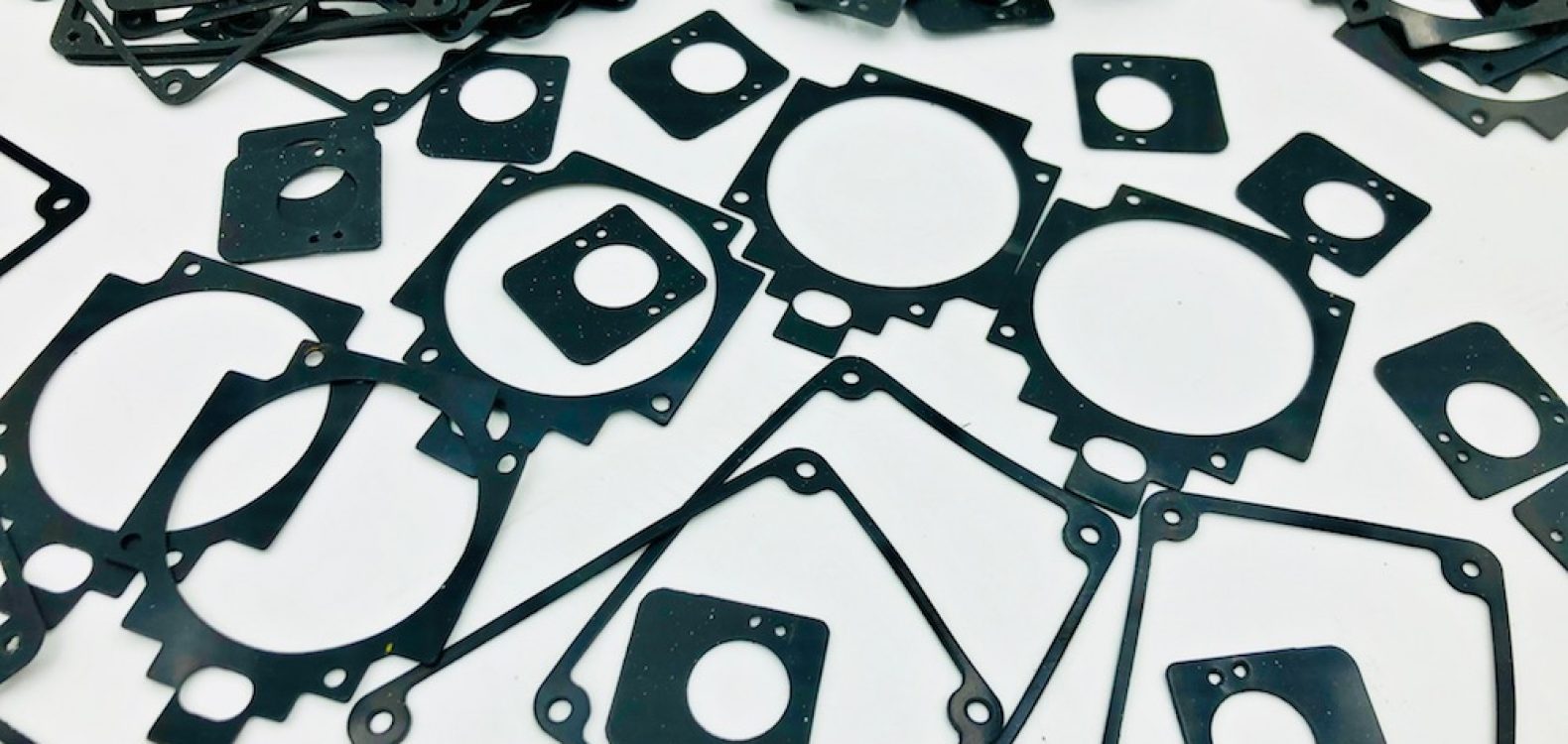

EPDM (Ethylene Propylene Diene Monomer) rubber seals, also known as EPDM gaskets or EPDM rubber gaskets, are widely used sealing components known for their excellent resistance to weathering, UV radiation, ozone, and a wide range of chemicals and solvents. EPDM rubber seals are commonly employed in various industrial, automotive, construction, and HVAC (Heating, Ventilation, and Air Conditioning) applications due to their durability and versatility. Here’s more information about EPDM rubber seals:

1. Material and Composition:

- EPDM Rubber: EPDM is a synthetic rubber compound composed of ethylene, propylene, and diene monomer units, which give it its unique properties. This material is known for its excellent weather resistance, flexibility, and temperature stability.

2. Sealing Performance:

- Weather Resistance: EPDM rubber seals excel in outdoor and exposed applications because they resist the effects of weathering, UV exposure, and ozone. This makes them suitable for use in seals exposed to sunlight and harsh environmental conditions.

- Chemical Resistance: EPDM rubber seals are highly resistant to a wide range of chemicals, including acids, bases, and solvents. They maintain their integrity even when in contact with many corrosive substances.

- Temperature Resistance: EPDM seals have good low-temperature flexibility and can withstand high temperatures without significant degradation. They remain elastic and maintain their sealing properties across a broad temperature range.

3. Compression Set Resistance:

- EPDM rubber seals exhibit low compression set, which means they can maintain their shape and sealing performance even after repeated compression and relaxation cycles.

4. Water and Steam Resistance:

- EPDM seals have excellent water resistance and can be used in applications where they come into contact with water, steam, or other fluids without losing their sealing properties.

5. Electrical Insulation:

- EPDM rubber is known for its electrical insulating properties, making it suitable for applications where electrical insulation is required.

6. Application Areas:

- EPDM rubber seals are used in various applications, including:

- Automotive seals: EPDM is commonly used for automotive door seals, window seals, and under-the-hood gaskets.

- Construction: EPDM seals are used in roofing systems, curtain walls, and window seals for building construction.

- HVAC: EPDM seals are employed in HVAC systems to seal ducts, dampers, and air-handling units.

- Industrial: EPDM seals find applications in industrial equipment, machinery, pumps, and valves.

- Marine: EPDM seals are used in marine applications, such as boat hatches, porthole seals, and gaskets for marine engines.

- Electrical: EPDM seals serve as electrical insulators in various electronic and electrical components.

7. Customization:

- EPDM rubber seals can be customized in terms of size, shape, and thickness to suit specific sealing requirements.

In summary, EPDM rubber seals are versatile sealing components known for their durability and resistance to environmental factors, chemicals, and temperature extremes. Their use is prevalent across a wide range of industries and applications where dependable sealing and longevity are essential.