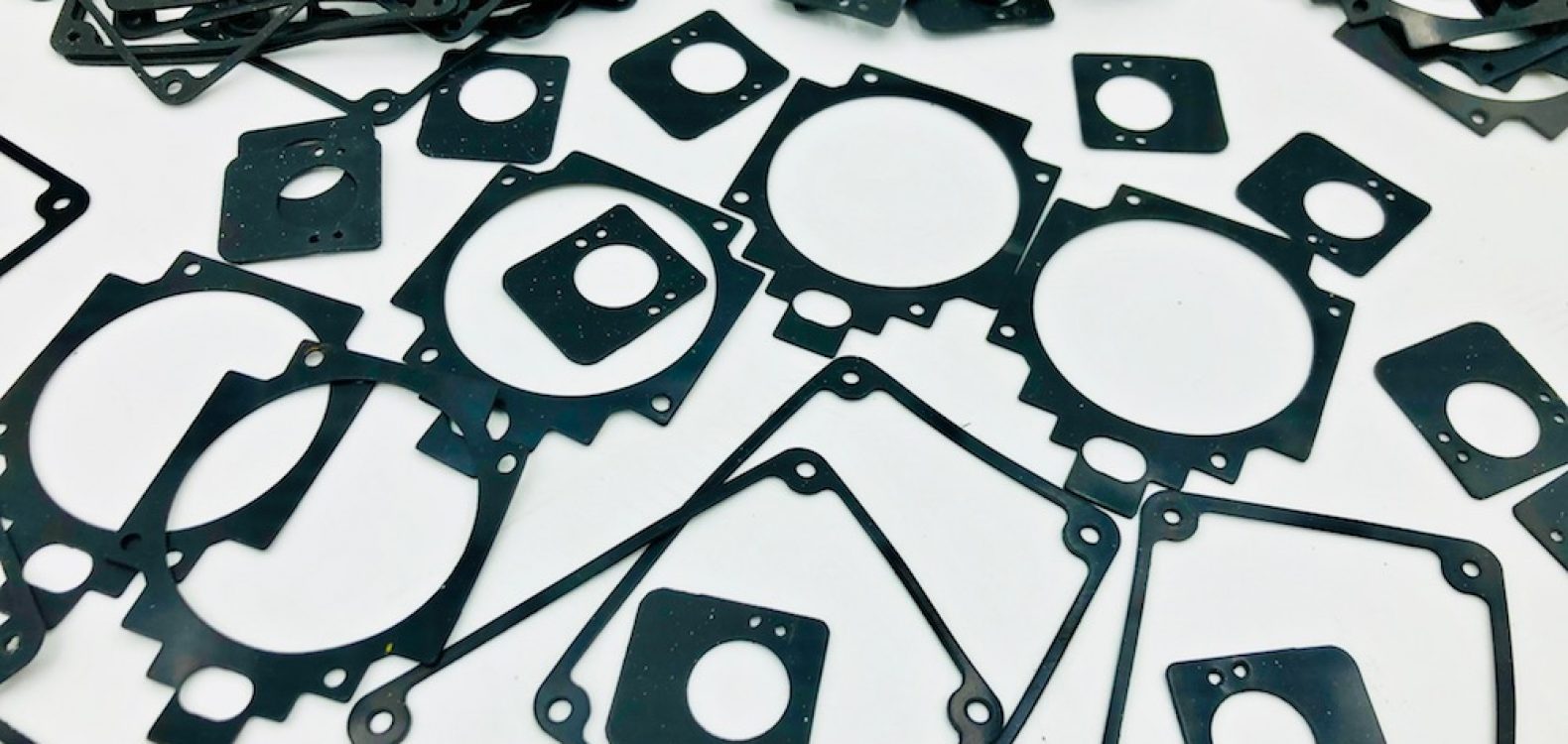

EPDM rubber seals and gaskets are widely used in various industries due to their excellent properties. Here’s an overview:

- Weather Resistance: EPDM exhibits exceptional resistance to weathering, ozone, and UV exposure, making it suitable for outdoor applications.

- Temperature Resistance: EPDM can withstand a wide range of temperatures, from -50°C to +150°C (-58°F to +302°F), without losing its elasticity or mechanical properties.

- Chemical Resistance: It is resistant to many chemicals, acids, and alkalis, making it suitable for applications where exposure to such substances is common.

- Water Resistance: EPDM is impermeable to water and steam, making it ideal for sealing applications in plumbing, automotive, and construction industries.

- Electrical Insulation: It has good electrical insulating properties, making it suitable for use in electrical enclosures and cable insulation.

- Flexibility and Elasticity: EPDM gaskets maintains its flexibility and elasticity over a wide temperature range, allowing it to adapt to various shapes and surfaces without losing its sealing capabilities.

- Tear Resistance: EPDM exhibits high tear strength, which ensures durability and longevity in demanding applications.

- Low Compression Set: EPDM resists compression set, meaning it can maintain its original shape and sealing properties even after prolonged compression.

EPDM rubber seals and gaskets find applications in automotive, construction, HVAC (Heating, Ventilation, and Air Conditioning), aerospace, and various industrial sectors where reliable sealing and gasketing solutions are required.