Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joints, are vital components used in the construction of concrete pipelines and sewer systems. These seals are designed to create watertight and secure connections between concrete pipes, ensuring the integrity and efficiency of the pipeline. Here’s more information about concrete pipe seals:

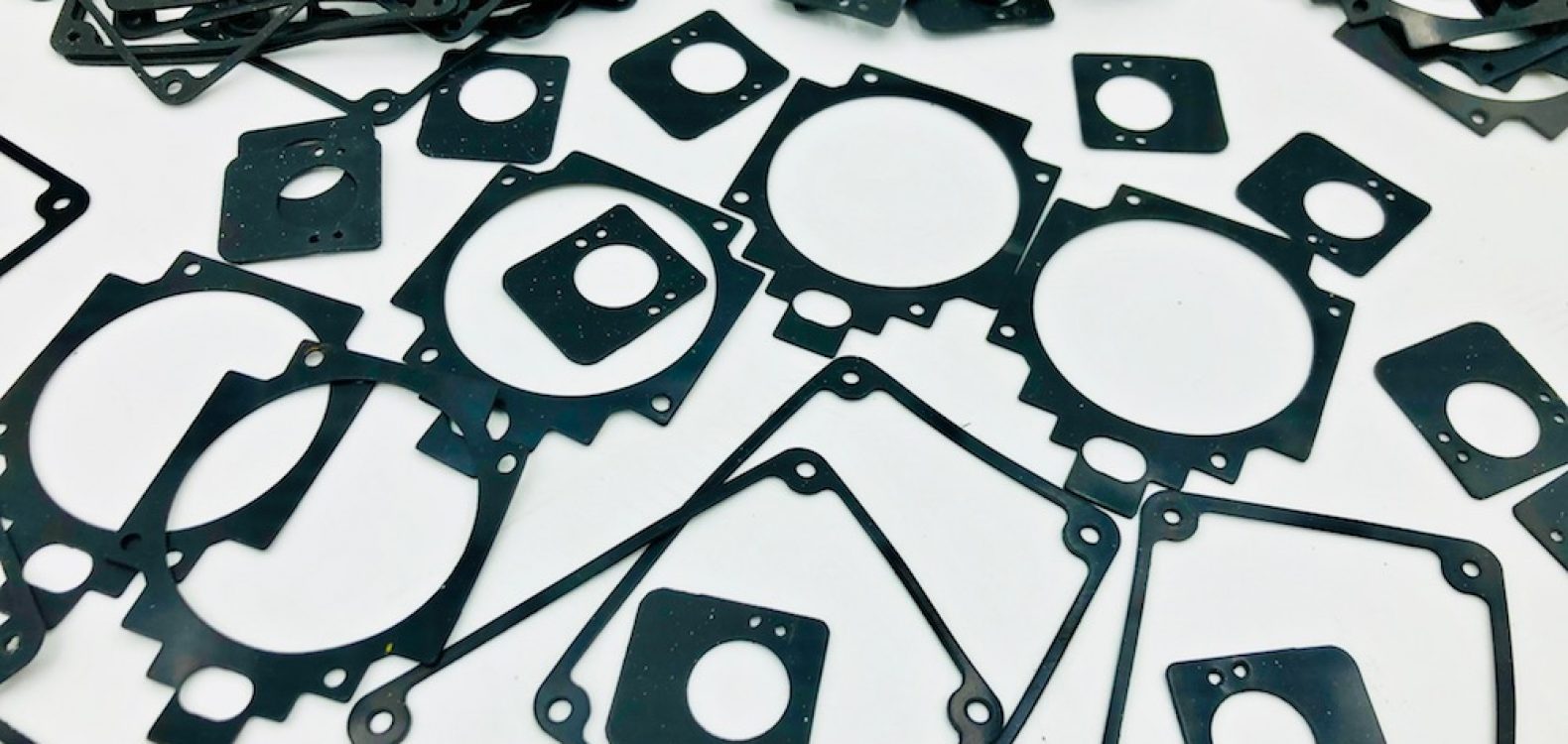

1. Material and Construction:

- Elastomeric Materials: Concrete pipe seals are typically made from elastomeric materials, such as rubber or neoprene. These materials provide flexibility and resilience, allowing the seal to conform to irregularities in the concrete pipe’s surface and create a watertight seal.

- Reinforcements: Some concrete pipe seals may include fabric or reinforcement layers to enhance their durability and resistance to compression.

2. Sealing Performance:

Concrete pipe seals are designed to provide an effective barrier against the infiltration of groundwater, soil, and contaminants into the pipeline. They prevent leaks and maintain the hydraulic efficiency of the system.

3. Resistance to Environmental Factors:

Concrete pipe seals are engineered to withstand a range of environmental factors, including UV exposure, temperature fluctuations, and exposure to chemicals commonly found in wastewater and drainage systems.

4. Joint Types:

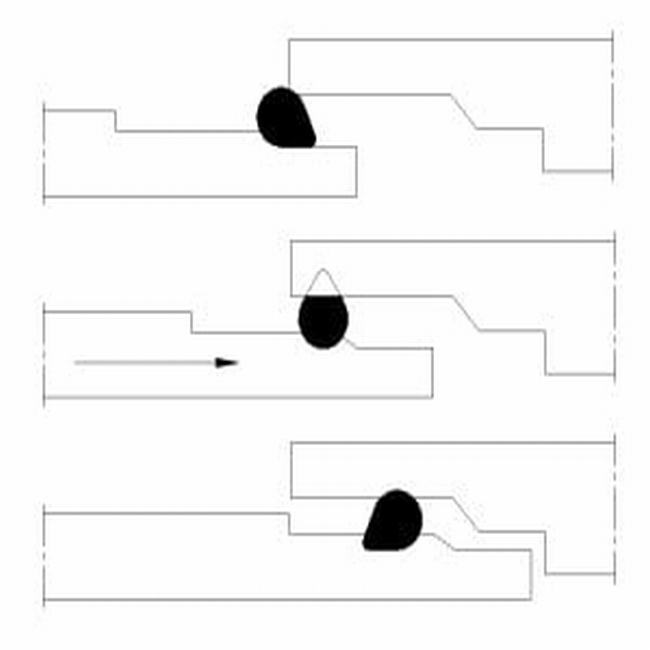

Concrete pipe seals can be used in various joint configurations, including:

- Bell-and-Spigot Joints: These joints feature a bell-shaped end on one pipe and a spigot end on the other. The seal is placed in the bell end, and the spigot end is inserted, creating a secure connection.

- Tongue-and-Groove Joints: These joints have interlocking tongue-and-groove sections that are sealed with the concrete pipe gasket.

- Mechanical Joints: Some concrete pipes use mechanical connectors, and the seal is used to create a watertight seal within the mechanical joint.

5. Easy Installation:

Concrete pipe seals are typically easy to install. They are placed in the joint before connecting the concrete pipes, ensuring a secure and watertight seal when the pipes are properly joined.

6. Customization:

Concrete pipe seals come in various sizes and shapes to fit different pipe diameters and configurations, ensuring compatibility with a wide range of concrete pipe systems.

7. Application Areas:

Concrete pipe seals are commonly used in applications such as sewer systems, drainage systems, culverts, stormwater management, and wastewater treatment plants. They are essential for maintaining the integrity of underground pipelines and preventing contamination of soil and groundwater.

8. Longevity and Maintenance:

High-quality concrete pipe seals are designed for long service life and minimal maintenance. Regular inspections may be necessary to ensure that the seals remain in good condition and continue to provide effective sealing.

In summary, concrete pipe seals are crucial components in the construction and maintenance of concrete pipelines and sewer systems. They play a vital role in preventing water infiltration, maintaining the efficiency of the pipeline, and protecting the environment by containing wastewater and contaminants within the system. Properly installed and maintained concrete pipe seals contribute to the long-term reliability of underground infrastructure.